Monday, April 20, 2015

Sunday, April 19, 2015

New resources for the end of the semester

I've been hard at work organizing documents into my Google Drive. Keep looking there for those missing assignments that you need to find.

Here's what's new:

Here's what's new:

- Google Drive Folder

- Shop Foreman Report

- Time Card (for participation credit)

- Woods I/II End of Semester Assignments

(You know... so you can plan ahead!) - Woods I/II First Semester Credit

(Finally, it's here! Pick your grade and earn it!)

Bad news: The shed project has been canceled.

Good news: More time for projects!

Monday, April 13, 2015

Starting to use Aspire for the CNC

So you want to learn how to use the CNC machine? Let's start with some basic software called Aspire. This will let you make anything from a simple name tag to a complex 3-d shape. Rather than re-create everything from scratch, I'm going to select a few of their tutorial videos for you to watch and then begin to learn the software on your own. Once you have tinkered around for awhile and are truly stuck, I will help you along.

Don't worry about messing up! The program will let you see the outcome of your work without wrecking the CNC machine. Once you have created something on the computer that you're ready to carve into wood, I'll check it before we venture over to the CNC for a satisfying session of sawdust-flinging fun.

For the full collection of video tutorials, go here:

http://www.vectric.com/support/training-material/aspire-vcp/2d-design.html

Step 1: Learn the interface (in other words, what all the buttons do...)

http://www.vectric.org/video/aspire3/2d_design/a2-interface-layout-web/a2-interface-layout-web.html

Step 2: Working with text

http://www.vectric.org/video/aspire3/2d_design/a3a-working-with-text-web/a03a-working-with-text-web.html

Step 3: Creating a toolpath

Step 3: Creating a toolpath

By now, you've watched nearly 50 minutes of video and have (hopefully) spent an equal amount of time working in Aspire to try some of those skills on your own. While the videos do show you how to make a toolpath, they don't show how to create one for our ShopBot. Here are a couple of things that you need to know.

Don't worry about messing up! The program will let you see the outcome of your work without wrecking the CNC machine. Once you have created something on the computer that you're ready to carve into wood, I'll check it before we venture over to the CNC for a satisfying session of sawdust-flinging fun.

For the full collection of video tutorials, go here:

http://www.vectric.com/support/training-material/aspire-vcp/2d-design.html

Step 1: Learn the interface (in other words, what all the buttons do...)

http://www.vectric.org/video/aspire3/2d_design/a2-interface-layout-web/a2-interface-layout-web.html

Step 2: Working with text

http://www.vectric.org/video/aspire3/2d_design/a3a-working-with-text-web/a03a-working-with-text-web.html

Step 3: Creating a toolpath

Step 3: Creating a toolpathBy now, you've watched nearly 50 minutes of video and have (hopefully) spent an equal amount of time working in Aspire to try some of those skills on your own. While the videos do show you how to make a toolpath, they don't show how to create one for our ShopBot. Here are a couple of things that you need to know.

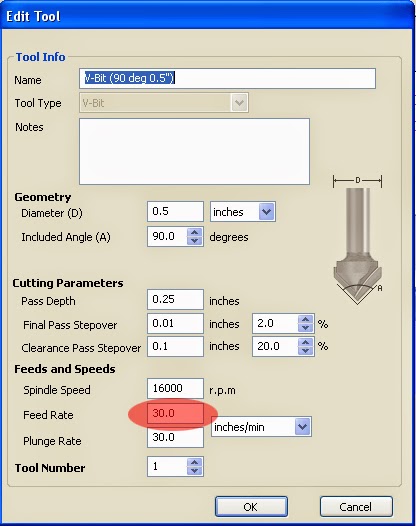

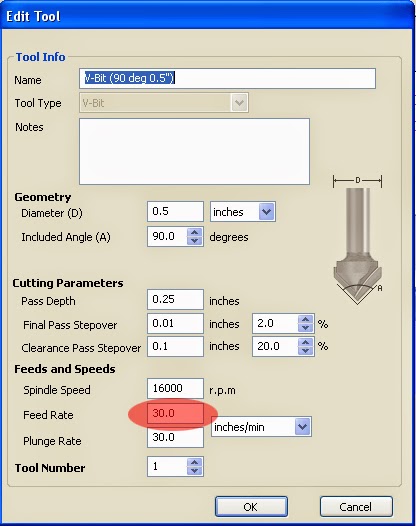

- When you choose a tool, be sure to choose the 0.5" V-Bit.

- Make sure that the feed rate is 50.0 (see illustration--I increased it a bit after some experimentation).

- When you save the tool path, you must choose the "ShopBot (arcs)(inch) (*.sbp)" selection.

- You will need to have a USB thumb drive in the computer. Be sure to save the toolpath to the USB stick.

- Important: The toolpath file is different than the Aspire file. After you export your toolpath, you must also save your working file. What's the difference?

- The toolpath file only has the codes to tell the ShopBot where to go: up, down, left, right. This will create a beautiful sign in wood (or plastic or foam or whatever). It doesn't tell the computer what font to use, only how to make the letters. This is the file that you will feed to the ShopBot.

- The Aspire file has all of the information the computer needs to edit what you have created such as the fonts and the words in the fonts. This file is useless to the ShopBot, but you must save it to make changes later.

You can create all of the toolpaths you want without fear of breaking anything. I will always check them before anything runs on the ShopBot!

Step 4: Independent Learning

Seriously, why would I do all of the work when it's been done already? Go to the link below and watch the video tutorials in order and practice in Aspire.

My suggestions to try:

- V-Carving letters

- Tracing images

- Creating a textured background

- Creating an inlay with two contrasting pieces

- Creating a 3-d shape to carve

Thursday, April 9, 2015

Stuff to build

One of the great outcomes of attending a CTE (Career and Technical Education) conference is steaming pile of ideas that I collect.

I got this from a Facebook friend:

Here's a link to a skateboard press that we can make:

I'd like to go a step farther and develop a profile in CAD and make it on the CNC router. Any takers?

Here's another version:

This video is good because it shows how much work that goes into the finishing process!

Here's an article on the science of skateboard design.

I got this from a Facebook friend:

Wednesday, April 8, 2015

Sunday, April 5, 2015

End of the term...

There will be a test on Thursday. This will be 20 percent of your grade! I have prepared a study guide for you. Do whatever you can to complete the study guide, including:

- Reviewing papers from class

- Reviewing your notes

- Asking a friend

- Asking the teacher

- Using the internet to search for the answer or additional information that might help you

I will be available during both lunches and after school on Monday (3:06-3:36) and Tuesday (3:06 - ???).

In the shared folders for each class, you will find a growing library of materials, including assignments that you may have missed. If you don't find what you're looking for, please e-mail me and I will add it if I can.

Coming soon:

Can I make gears on the CNC machine? What else can I make on the CNC machine? What tools can we find in the shop that have been buried since 1989 (I've found a few!) What plans can I find online that we could make before June. Here's one that I've been considering...

Or maybe...

Or just look at this guy's web site:

Subscribe to:

Comments (Atom)